Centre of Excellence

Center of Excellence is a facility with necessary infrastructure to enhance the skills of the students. These centers provide ample opportunity for the students and faculty to comprehend the latest industry practice and upgrade their knowledge through industry relevant projects using these facilities and the industry know-how. Centre offers to upgrade the prowess of the student and faculty about the current trend in industry as well, also serving as a revenue generating model. Center of Excellence provides way to strengthen ties between the institute and the industry.

- Automation & Robotics

- Automobile Excellence Centre

- Bio-Fuel Research Centre

- Materials Research Centre

- Product Design & Development

Automation & Robotics

The Flexible Manufacturing System Centre has been established to provide training on par with the requirement of the industry. This Centre entered into a collaboration arrangement to extent the knowledge to the students, Industries and practicing professionals. The vision behind it is to promote and encourage student activities, research projects and relevant courses related to this field.

Establish Research facilities in the area machining.

Undertake the research projects to meet the requirements of the Industry

To serve as a link between Industry and Academia and provide Consultancy

To provide hands on training on Robot Programming

CNC Vertical Milling Centre

CNC Lathe

Robot – Five Axis rotation – Articulated 5-Axis, 360º rotation

Simulation software using capsturn/capsmill

Consultation work

A few research project works have been carried out for the research scholars.

Research and consultation works have been carried out in the small industry which is situated in and around the college premises.

Photo Gallery

Automobile Excellence Centre

Automobile Excellence center has been designed to target and cater to the end to end training and development needs of the automobile ecosystem. The center hosts latest state of the art infrastructure and tools to provide a hands on learning experience to the students. The lab is dedicated for student to reinforce their practical skills apart from their academics.

To impart the basic theoretical and practical knowledge on Automotive technology

To train the students in the field of Automobile Engineering to meet the industrial needs.

To create an awareness in the recent trends in the field of Automobile Engineering through a forum.

To participate in national level automotive race competitions, students design & manufacture their vehicles for various national level competitions such as SAE BAJA, SUPRA, Go-Kart, ESVC event.

Two wheeler chassis dynamometer

Coil spring test rig

Chain tension test rig

Shock absorber test rig

Emission Measuring Instruments for Petrol & Diesel Engines

Eco Sport vehicle provided by Ford India Pvt.Ltd for learning purpose of Students.

BMW engine provided by BMW India Pvt.Ltd for learning purpose of Students.

The center has arranged Internship training and Industrial project in various Industries

Photo Gallery

Bio-Fuel Research Centre

To create the awareness to the students about the alternative fuels derived from organic matters. Since, bio-fuels derived from organic matters has played a vital role in the environmental issues to reduce the emissions.

Also, to impart the knowledge to the students about the different methods of preparation of biodiesel.

To have the opportunity to tie-up with the industries.

Exchange of technical ideas between the industry and the institution has been strengthened.

Students have most benefited from them to acquire the knowledge in the field of the latest advancement in engines as well as in alternative fuels.

The industry and institution gap has been bridged.

Possibility to bring the innovative projects in the field of I.C.engines.

Single cylinder four stroke diesel engine is available to conduct the experiments.

Exhaust gas analyzer (five gas analyzer), Smoke meter unit is available.

Various testing equipment such as Viscometer, bomb calorimeter etc. is available to measure the properties of biodiesel.

Combustion analyzer is equipped with the engine to plot the various graphs such as pressure-crank angle, heat release rate and mass fraction burnt etc. while the engine is on running.

A few research project works have been carried out for the research scholars.

Research and consultation works in the field of alternative fuels have been carried out in the small industry which is situated in and around the college premises.

Various student projects in alternative fuels have been carried out.

Photo Gallery

Materials Research Centre

Materials are real blessings to mankind; in the modern technological worlds the need of the day is advanced materials for growing technological advancements. The Composites are most sought engineering materials due to its wide span of applications in well prominent field of engineering.

To provide Hands on training in preparing composite materials.

To provide Information’s pertaining to composite material strength and its mechanical behavior.

To Provide consultancy work in the area of metal matrix composites.

To Carry out fiber reinforced Laminate design for different combinations of plies with different orientations of the fiber.

To Carry out corrosion study on Engineering materials.

To find avenues in most appropriate composite material development.

To develop composite materials in an optimized way.

To characterize the various important aspects of Composite materials.

Computerized Universal Testing Machine

Brinell Hardness Testing Machine

Compression Testing Machine

Fatigue Testing Machine

Impact Testing Machine

Rockwell Hardness Testing Machine

Vickers Hardness Testing Machine

Torsion Testing Machine

Stir casting furnace for Aluminium / Magnesium

Photo Gallery

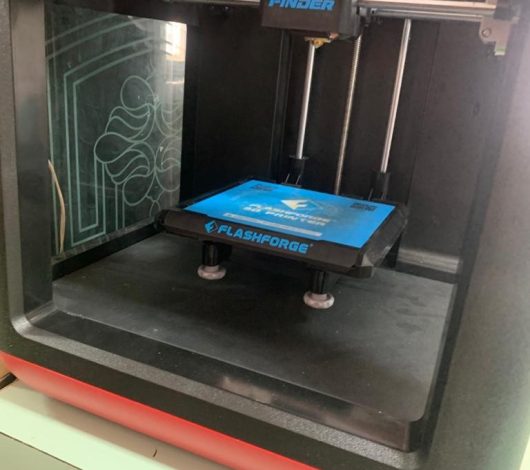

Centre For Product Design & Development

The Centre for Product Design and Analysis has been established to facilitate the students to learn design and analysis of products/components using various modelling and analysis software through direct forum based training and online educational platform. We focus on providing the advanced engineering coursework/training to Mechanical Engineers. Our courses are offered to students through faculties and by expert members who have been working in design and analysis field.

To impart the basic theoretical and practical knowledge on design and analysis

To train the students in the field of design and analysis to meet the industrial needs.

To create an awareness in the recent trends in the field of design and analysis through a forum.

To develop engineers who are willing to learn industry oriented software applications with a problem solving approach. The course is designed by considering Engineering Design & Manufacturing of the parts, after completion of the course candidate will be able to match the industry expectations in their chosen profession.

This forum has been established to train the interested students in the design and analysis field inside the campus through our faculties. The main objective of this forum is to impart the knowledge on the fundamental software to design the basic components.

The details of the basic Software are as follows:

AUTOCAD

PROE

SOLID WORKS

ANSYS